INDUSTRY

- Automotive

SERVICES

- Change & Learning

- Service Design & Communication

1 minute a day to look at Quality with a different set of eyes by creating a connection between the end user and employees.

A program to change the mindset on Quality in the factory.

Each day, from foundry to assembly, employees of the Stellantis Group perform every stage of production, playing a fundamental role in the Quality process.

Quality that, in the daily life of the factory, translates into figures – numbers in production defects and achieved goals – thus making employees lose sight of the correlation between their daily work and the experience of the end user.

The Group has considered it strategic to involve employees at European level in the process of changing both their mindset and their approach to questions of Quality, so placing end-user satisfaction at the very centre of the production chain.

1 minute a day to trigger change

A Logotel team based between Milan and Paris comprised of service designers, behavioral designers, visual designers, content creators and copywriters supported Stellantis at every phase of YES Factory’s design and construction, developing the entire physical-digital ecosystem and accompanying the factory in carrying the program out and taking it forward.

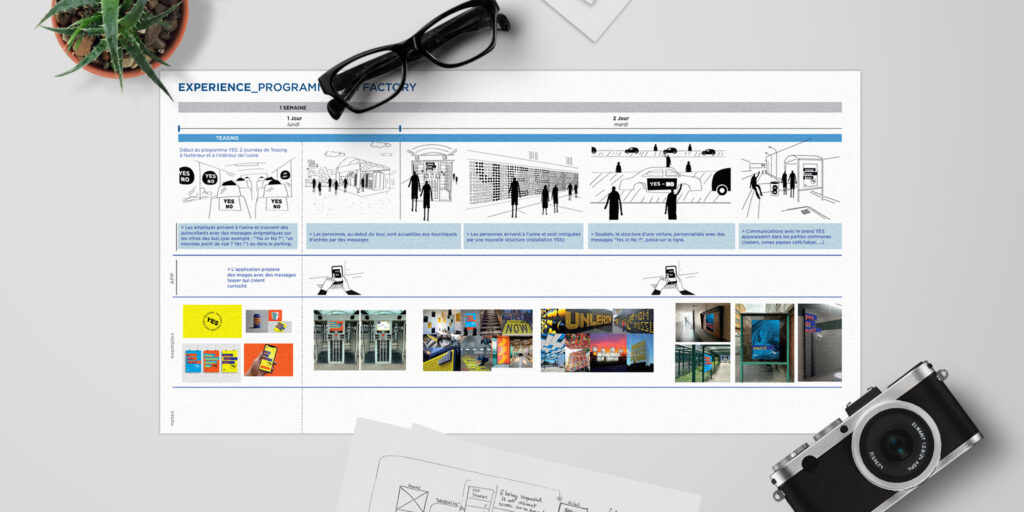

YES Factory is an experience that consists of a schedule of daily interactive micro-activities performed by managers and their employee teams – all anchored in a support and accompaniment structure comprising moments of co-design, training and realization of physical and digital tools – all the while enriched by a communication strategy that increases the program’s impact upon the factory.

A program in line with employee needs

The first project steps focused upon understanding the situation in the factories in order to find solutions that can best respond to the needs expressed by the European Quality team: mapping the limits and opportunities linked to the context in which employees work on a daily basis.

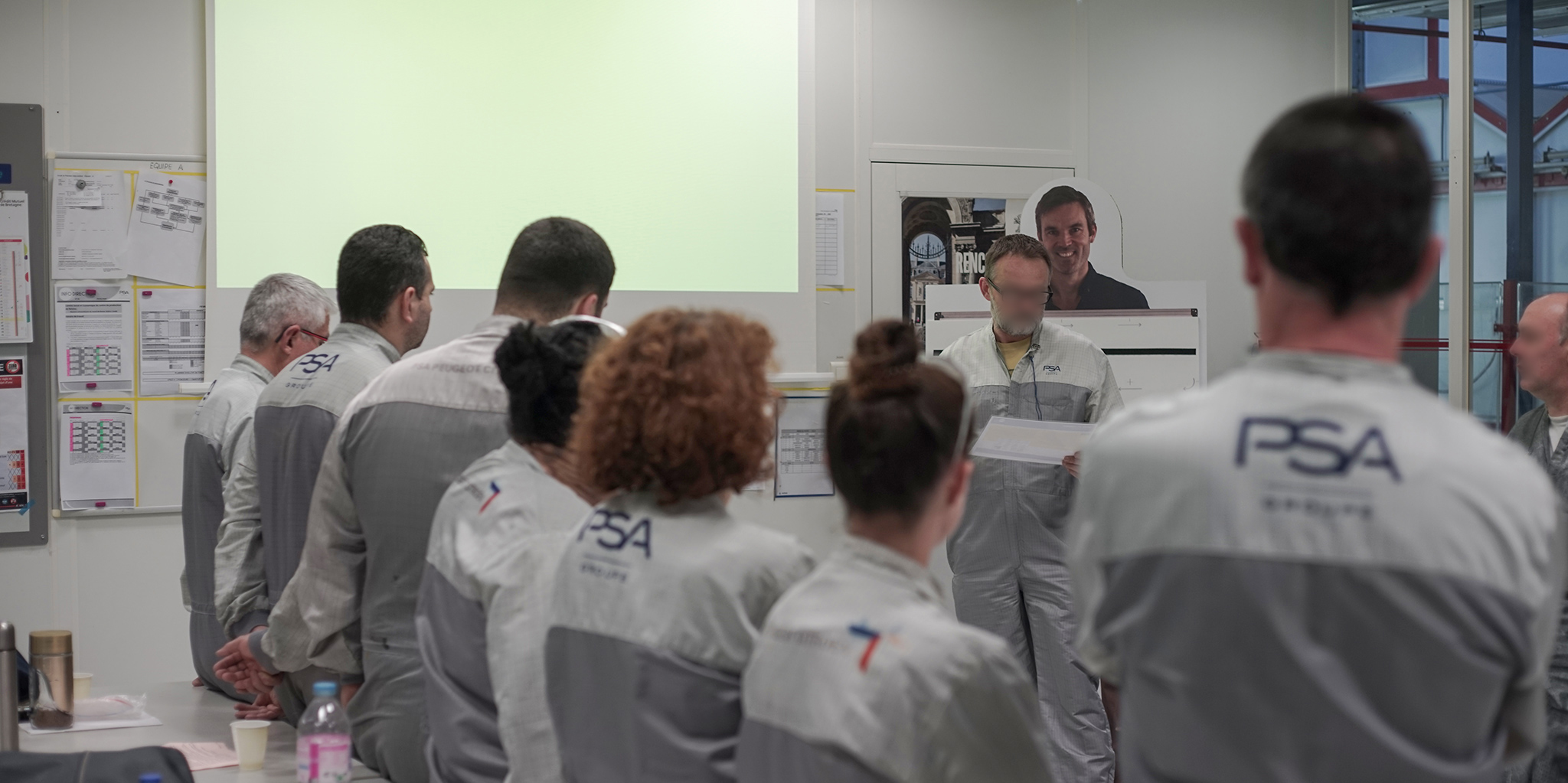

Moments of discussion with all the factory roles were necessitated. We actively involved the front lines as well as the industry and communication managers. Together we identified the values by which to articulate the question of Quality while defining action perimeters and testing activities.

This process of systematic involvement of the whole factory was decisive in contributing to the program’s success, making it possible to overcome at every level the natural resistance to change while bringing aboard the initiative those who knew how to make their own YES Factory approach and translate it into concrete actions.

Website, video tutorial, infographics,

physical kits, best practices

We have accompanied the factory through every step leading up to the program’s grounding, guiding the teams in logistics management, materials creation and internal communication.

We have trained all those directly involved in management of the activities, both in presence and remote, providing them with the tools to carry out the program, independently, in the best possible way.

In addition to equipping them with physical kits containing the materials for use during activities throughout the program, we have created a website where they can find video-tutorials, infographics and tips to facilitate preparation and the exchange of best practices.

A playful

and interactive approach

The 1-minute activities were arranged with a view to having the team manager address the question of Quality from a different, day-to-day perspective so as to keep engagement high while arousing curiosity. Whether we’re speaking of Quality by relating the story of a customer’s experience, however satisfied or dissatisfied, or of compliance with safety standards that allow everyone to work at their best, activities are united by a playful, interactive approach. The physical support, of immense visual impact, allows all workers to participate in activities while rendering the customer’s presence in the factory more tangible. Besides the tools used for the 1-minute activities we have created a guerrilla comprising communication elements that “invade” the factory space – from turnstiles to entrance to passageways to external areas – all to amplify the impact of the initiative.

Workers involved

6000+

Km of tape

25+

Training sessions

30+

Kits delivered

500+